Access to the Design, Prototyping, and Testing Laboratory

The types of products that can be tested in the laboratory, in accordance with the acquired quality standards, are:

- Office furniture;

- Home furniture;

- Outdoor furniture.

The Design, Prototyping, and Testing Laboratory, equipped with 19 different devices, address to professionals who need prototyping or testing equipment, such as industrial designers, creators and object designers, as well as representatives of companies in the wood and furniture industry, who wish to ensure that their final products are of good quality, meeting European standards. The testing operations show you how your products stand up to wear and tear over time.

Access to the laboratory is exclusively by appointment, which can be requested at the email address testare@mobiliertransilvan.ro. Subsequently, you will be contacted to organize and prepare the necessary assistance, thus ensuring the optimal conduct of the testing process.

The laboratory is located within the Regional Center of Excellence for Creative Industries (RCECI, strada Tiberiu Popoviciu, nr. 2-4) and was established through the European project Cluj – Future of Work, the first project in Eastern Europe funded by the European Commission through the Urban Innovative Actions research and development program. Cluj – Future of Work is co-managed by the Cluj-Napoca City Hall and the Cluj Cultural Center, in a consortium with eight other local organizations, including the Transylvanian Furniture Cluster.

Design, Prototyping, and Testing Laboratory Infrastructure

-

Testing services for chairs, sofas, tables, loungers, mattresses, beds, and armchairs

- Determining product dimensions

- Testing security requirements

- Determining product stability

- Determining product strength and durability

Tests with RENAR accreditation

- Tables

- SR EN 527-1:2011 point 4.1 and 4.2

- Storage Furniture

- SR CEN/TR 14073-1:2005 point 6.1, 6.2 and 6.3

- Beds and Mattresses

- SR EN 1334:1999 point 6.1, 6.2 and 6.3

- Chairs

- SR EN 1022:2019

- SR EN 1729-2:2023 point 6.2

- Storage Furniture

- SR EN 14073-3:2005 point 5.5

- SR EN 16122:2012 point 11.1,11.2, 11.3, 11.4 and 11.5

- SR EN 16122:2012/AC 2015

- Chairs

- SR EN 16139:2013 point 5 and 6

- SR EN 1728:2012 point 6.4, 6.5, 6.6, 6.10, 6.11, 6.13, 6.15, 6.16, 6.17, 6.20, 6.24, 6.25, 6.26, 7.3, 7.4, 7.5, 7.6 and 7.7

- SR EN 1728:2012/AC:2013

- SR EN 12520:2016 point 5.4

- SR EN 1729-2:2023 point 6.3

- SR EN 12727:2017 point 5.

- Tables

- SR EN 527-2+A1:2019 point 5

- SR EN 1730:2013 point 6

- SR EN 15372:2024 point 5.5

- SR EN 12521:2023 point 5.5 and 5.6

- Storage Furniture

- SR EN 16121:2024 point 6

- SR EN 14749+A1:2022 point 5.3

- SR EN 16122:2012 point 6, 7 and 8

- SR EN 16122:2012/AC:2015

- Beds and Mattresses

- SR EN 1725:2023 point 6.6

- Outdoor Furniture

- SR EN 581-2:2016 point 6.2 and 7.2

- SR EN 581-2:2016/AC:2016

- SR EN 581-3:2017 point 5

- Chairs

- SR EN 16139:2013 point 5 and 6

- SR EN 1729-2:2023 point 6.3

- SR EN 1728:2012 point 6.17, 6.18, 6.19, 6.20, 6.21, 7.3, 7.9, 8.4, 8.5, 8.6 and 8.7

- SR EN 12520:2016 point 5.4

- SR EN 12727:2017 point 5

- Tables

- SR EN 527-2+A1:2019 point 5

- SR EN 1730:2013 point 6

- SR EN 15372:2024 point 5.5

- SR EN 12521:2023 point 5.5 and 5.6

- Storage Furniture

- SR EN 16122:2012 point 7.1.5, 7.2.3, 7.3.2, 7.4.2, 7.5.3 and 7.6.4

- SR EN 16122:2012/AC:2015

- Beds and Mattrasses

- SR EN 1725:2023 point 6.6

- Outdoor Furniture

- SR EN 581-2:2016 point 6.2 and 7.2

- SR EN 581-2:2016/AC:2016

- SR EN 581-3:2017 point 5

Tests without RENAR accreditation

- Partition Walls

- SR EN 1023-1:200

- Partition Walls

- SR EN 1023-2:2002

- Outdoor Furniture

- SR EN 581-1:2017

- SR EN 581-2:2016

- SR EN 581-2:2016/AC:2016

- SR EN 581-3:2017

- Beds and Mattresses

- SR EN 1725:2004

- Chairs

- SR EN 1335-2:2019

- SR EN 16139:2013

- SR EN 12520:2016

- SR EN 1729-2+A1:2016

- SR EN 12727:2017

- Tables

- SR EN 527-2+A1:2019

- SR EN 15372:2017

- SR EN 12521:2016

- Storage Furniture

- SR EN 14073-2:2005

- SR EN 14749:2016

- SR EN 16121 +A1:2018

- Partition Walls

- SR EN 1023-3:2002

- Beds and Mattresses

- SR EN 1957:2013

- Chairs

- SR EN 16139:2013

- SR EN 1728:2012

- SR EN 1728:2012/AC:2013

- SR EN 12520:2016

- SR EN 1729-2+A1:2016

- SR EN 12727:2017

- Accessories

- SR EN 16337:2013

- SR EN 15939:2019

- SR EN 15338+A1:2010

- SR EN 15706:2009

- SR EN 14072:2004

- Tables

- SR EN 1730:2013

- Testing of Paints and Varnishes

- SR EN ISO 16474-2:2013

- Plastic Materials

- SR EN ISO 4892-2/A1:2013

- Textile Materials

- Resistance of dyes to artificial light SR EN ISO 105-B02:2015

- Resistance of dyes to artificial weathering SR EN ISO 105-B04:1999

- Resistance of dyes and degree of aging under artificial light and high temperatures SR EN ISO 105-B06:2020

- Exposure to filtered radiation from a xenon arc lamp SR EN ISO 105-B10:2012

-

Testing and measuring emissions of volatile organic compounds (carcinogenic agents)

The laboratory is divided into three areas, each dedicated to a specific process: development, prototyping, and testing of the final product.

The development area includes 2 workstations where specific industrial design and product rendering software can be used: the workstation with engineering software and the workstation with visualization software, which can then be visualized virtually using the VR & AR technology present in the laboratory.

The second area of the laboratory is dedicated to prototyping through 3D printing technology, using the laboratory’s filament 3D printers, as well as one that uses both filament and clay.

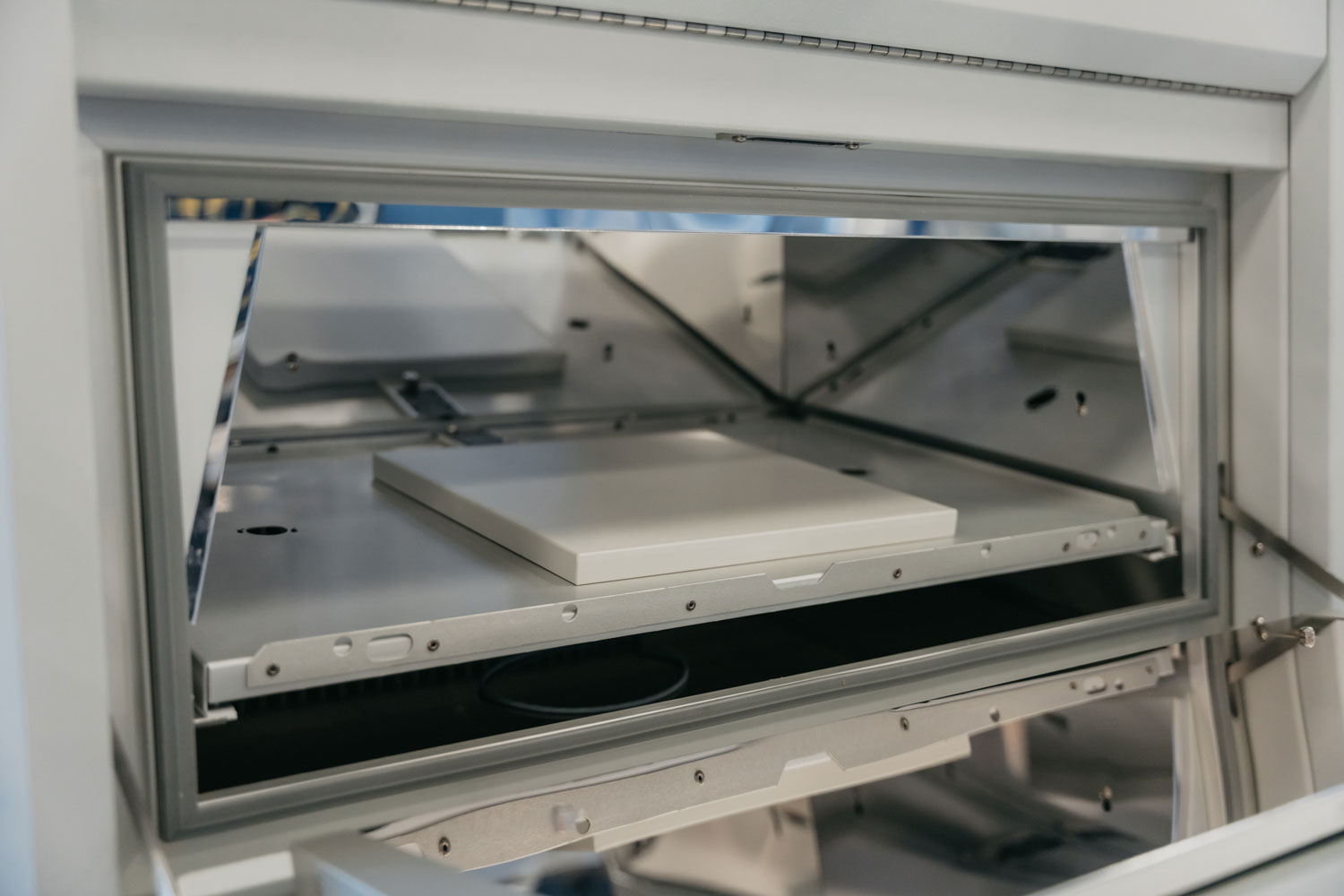

The final product testing area includes equipment for testing strength, durability, and stability, as well as for testing the aging of artificial surfaces, which simulate the product’s resistance to weather factors such as rain, fog, and sunlight (UV). Another accessible piece of equipment is the emissions testing booth, which determines whether the produced item releases harmful substances.